Maximum availability and material resistance

When it comes to EDGE computing, the IT sector sees it offering growth prospects on the one hand, and on the other, as a unique opportunity to reduce real-time communication delay times (latency) between the sensor and actuator. And this is an absolute necessity when it comes to autonomous driving, for example.

In reality, this means that EDGE computing must be in close proximity to the actual application. This challenges technology in completely new ways since the application could be in a harsh industrial environment or out in the open field – as is the case with autonomous driving. Manufacturers of outdoor housings, containers and air-conditioning technology will not only take on this challenge, but master it too. Yet initial experiences have revealed a new and thus far underestimated phenomenon: Dew or condensation.

We’ve all been there: after a morning shower, you’re standing in front of the mirror and can’t see anything because a veil of tiny water droplets is covering the surface. But it can simply be wiped away. But when it comes to EDGE computing out in the open field, that doesn’t work – logically.

How and why does condensation occur?

Condensation always occurs when a substance (in this instance, hydrogen H2) changes from a gas into a liquid. Humidity – in the form of water vapour – can always be found in the air. The warmer the air, the more water it can absorb. (Evaporation in summer) If this warm air hits a cold medium, it cools down resulting in condensation. When it comes to our bathrooms, the warm air saturated by our shower hits the much cooler mirror or bathroom window, transforming the air into the water drops we’ve all seen before.

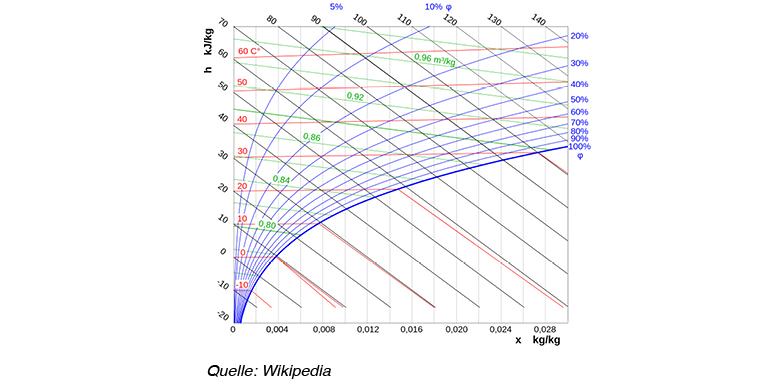

Air-conditioning technicians can predict the dew point using the Mollier h-x diagram.

Here’s an example:

The temperature of the EDGE data centre is 32 °C (e.g. in the hot aisle) and the relative humidity is 70%. If this air hits cool components with a temperature of 20 °C (e.g. air-conditioning refrigerant or water pipes), this results in condensation. This is illustrated by the blue-shaded area on the following h-x diagram.

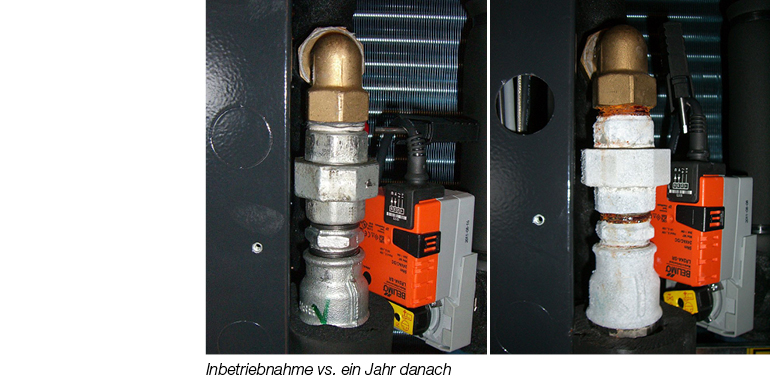

Commercial and also specific air-conditioning equipment for the data centre features an active (condensate tray + pump) or passive (condensate tray + outlet) condensation management system. Why? Because the phenomenon mentioned above is well known and ever-present. But when it comes to EDGE computing, who can be sure that only the air-conditioning technology connections will be affected? It’s hard to imagine what could happen if dew drops also formed near the IT equipment and was drawn inside by the air flow. Minimal condensation lasting only a short period will not affect functionality. However, in the long term, the material may become damaged by corrosion as shown in the following photos:

Monitoring climate parameters (temperature, relative humidity, air flow, air pressure, etc.) is now standard in any data centre and should also be found in every EDGE computing centre (e.g. container solutions). But how many IT administrators or data centre operators can recognise the danger of dropping below the dew point based on temperature and relative humidity?

The BlueNet series (BN3000 - 7500) offers an intelligent solution. Using our combined sensors, we can measure the temperature and relative humidity in the hot and/or cold aisle, for example. The controller on every BlueNet PDU (power distribution unit) uses these measurement results to calculate the dew point and sends a report to the facility management system via SNMP trap or isolated contact if a threshold limit value is going to be exceeded. Prevention follows information. The following scenarios are possible preventative countermeasures:

Whichever of these measures is the preferred solution, information on exceeding the limit value is needed as a starting point.

Author: Tilo Püschel, © Bachmann GmbH 2019